Your automated warehouse system needs a much higher FF/FL tolerances than standard warehouses. Uneven surfaces can slow down your robots, cause errors, and lead to extra wear and tear. You need a robotic fulfillment flooring solution built for the precision demands of modern logistics.

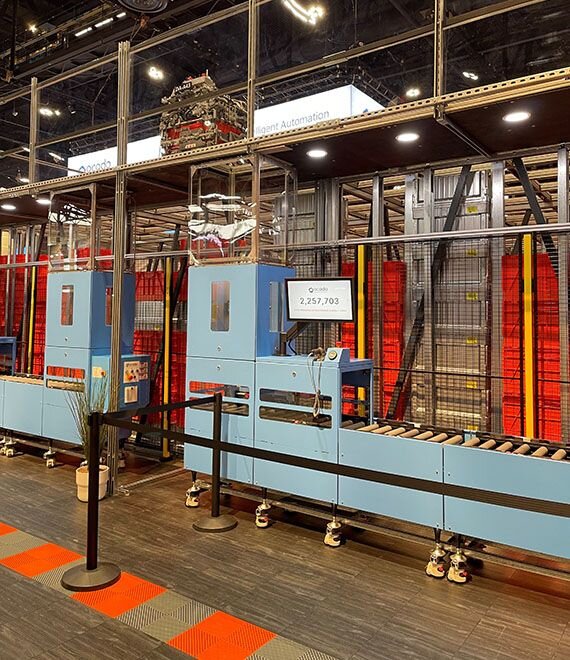

Count on BNE for expert flooring solutions engineered for Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), and AutoStore systems.

Maximize Robot Efficiency. Get the most out of your automation investment with a surface built for smooth, uninterrupted operation.

Reduce System Errors. Minimize navigation problems and operational glitches caused by uneven floors.

Protect Your Equipment. A flat, stable surface reduces stress and wear on expensive robotic components, extending their lifespan.

Don't let uneven flooring hold back your automated systems. Call us or fill out our contact form to speak with an experienced sales representative today.

CONTACT OUR SALES REP

Make the right choice for your automated warehousing facility. BNE delivers the best AGV/AMR floor preparation, highest quality workmanship, and the peace of mind that comes with our BNE Promise.

![]()

Expertise you can trust. Our dedicated team brings decades of experience to your ultra-flat AGV/AMR flooring project. Expect clear communication, efficient execution, and on-time on-budget delivery.

![]()

Save the hassle of multiple contractors. BNE manages every part of your automated warehouse flooring project, from assessment to application. This lets us ensure that you see seamless, high-quality results as promised.

![]()

Engineered for performance and value. We provide in-house value engineering to save you time and money without compromising on the performance of your automated warehouse flooring.

Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), and storage systems like AutoStore absolutely depend on floors built to incredibly precise flatness (FF) and levelness (FL) tolerances. Whether robots run directly on the concrete floor or on a mezzanine structure supported by it, the surface underneath must be ultra flat, because even small bumps or dips can cause problems.

Uneven floors force robots to slow down or adjust their path. An ultra-flat floor designed to meet FF/FL tolerances for robotics allows robots to operate consistently at their intended speeds without frequent stops or changes. This helps keep work moving steadily.

Bumps, dips, or uneven joints in the floor can confuse a robot's navigation system. This causes robots to follow the wrong route, get stuck, go offline (requiring manual intervention), or make mistakes when picking or placing items. Eliminating these surface flaws helps your automated systems run smoother with fewer interruptions or errors.

Driving over uneven floors causes constant vibration, which puts extra stress on sensitive and expensive robotic components like wheels, bearings, sensors, and motors. Over time, this causes more wear and tear. A flat floor designed for AGV/AMR warehousing helps to keep vibration at a minimum.

Getting a floor perfectly flat requires expertise and the right approach. BNE uses two main methods for robotic fulfillment flooring depending on your floor's current condition and your project timeline.

First, we work with a specialized floor surveying service. They use precise instruments to map the exact highs and lows across your existing concrete floor.

Using this detailed map as a guide, our team uses specialized concrete grinding equipment to carefully grind down the high spots.

Throughout the process, we continuously take measurements to make sure that we are meeting the FF/FL tolerances for robotics and moving the job along efficiently.

When a floor is too uneven or has too many large high and low spots for grinding to be practical, we instead apply a specialized cementitious overlay.

Cementitious overlay is poured as a liquid and is designed to flow and spread out evenly across the existing floor, naturally creating a very flat, smooth, and level surface as it cures. This method essentially builds a new, perfectly flat floor surface on top of the old one.

While the initial cost might be higher than grinding, using a levelling overlay is often faster, minimizing downtime and allowing your facility to get back to operation sooner.

No two warehouses are exactly the same. Your facility, automation system (whether it's AutoStore or another brand), and operational needs require a carefully engineered approach, not a generic fix.

We start by understanding the demands of your robotic systems and your current floor conditions. Based on this evaluation, we recommend the best method (grinding, levelling, or a combination) to achieve the required FL/FL tolerances by robotics, as described above.

Then, leveraging our extensive knowledge of concrete floor coatings, we can consult with you on the ideal surface finish considering factors like durability, chemical resistance, and slip resistance needed for your operations.

Our job is to find the best overall solution for you. We focus on delivering long-term value and performance, making sure that your ultra-flat robotic fulfillment floor and its finish support your automation investment for years to come. Our team knows these products inside and out. In fact, coating manufacturers often consult with BNE on our application techniques and best practices.

We'll work with you to make sure the chosen solution is a perfect fit for your needs and budget.

BNE has the knowledge, experience, and resources to complete your ultra-flat flooring project on-time and on-budget. You can trust the BNE Promise.

Speak with a BNE expert to discuss your project today.